Waterman Safeties

![]()

Although other manufacturers had offered retracting-nib safeties since just before the turn of the century – most notably, the straight-action Moore Non-Leakable – Waterman's entry into the market expanded the design's acceptance exponentially.

Waterman began advertising their new safeties by April 1908. Initially they were offered in only three sizes (12VS, 14VS, 15VS, each in just one standard length) with the option of gold filled barrel bands and the choice of smooth or chased black hard rubber, or "Cardinal" red hard rubber. The 1908 Waterman catalog, published at the beginning of October, extended the offerings to include standard and short models, as well as silver filigree overlay.

![]()

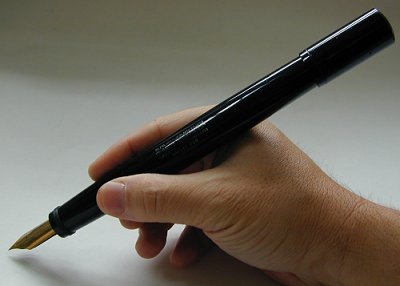

Early models had a threaded turning knob at the end of the barrel, onto which the cap could screw (a feature later copied by Kaweco in Germany) and a helically-cut track inside the barrel, so that the nib turned in relation to the barrel as it was extended and retracted.

The threads appear to have been eliminated from the end knob somewhere between 1911 and 1912 (an ad from May 1911 still shows a threaded knob, as does the British December 1910 Pen Prophet; in the Fall 1912 Pen Prophet the threads are gone). At around the same time, the tracks inside the barrel were made straight, so that the nib traveled forward and back without turning, propelled by a helically slotted tube (usually termed a "spiral") attached to the turning knob. The previous arrangement was adopted to avoid infringing US patent 523,234 of 1894, owned at the time by the Modern Pen Company. This key patent expired in July of 1911.

Although one finds pens with the earlier internal mechanism that have the later, unthreaded end knob, it is likely that in most such cases the end knob has been replaced. The earlier threaded knobs were easily chipped and broken, as the exposed flange was quite thin. When replacing the seal, the central shaft is driven out of the end knob with a punch. The flange supports the knob in this operation, receiving all the force of the hammer. The thicker, unthreaded flanges are quite sturdy, but with the threaded end knobs one can easily break off the entire flange with one light tap. Given the risk, we will not usually replace the seals on Waterman safeties with threaded knobs.

By 1912, Waterman had introduced a range of new overlay patterns for its smaller models, including full overlays, telescoping caps, and chatelaine suspension hooks.

The largest Waterman safety was the 20, carrying a huge #10 nib; the smallest was the safety version of the more common cone-cap "World's Smallest" miniature. Both are now rare and valuable.

Repair of Waterman safeties is straightforward, and even easy now that properly-sized O-rings are available to replace the original cork seals. Full details on how it is done here.

UPDATE: Recent research has revealed that the helical-track safeties were briefly preceded by a straight-track design that was quickly withdrawn after the Modern Pen Company protested the infringement of their patents. In court transcripts Waterman's representative stated that only a dozen or so had been sold. No surviving examples have been identified to date.

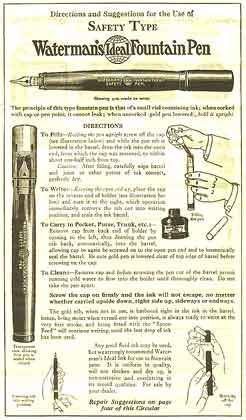

Original 1920s Waterman eyedropper instruction sheet

Practical advantages of safety pens

Link to Waterman safeties for sale